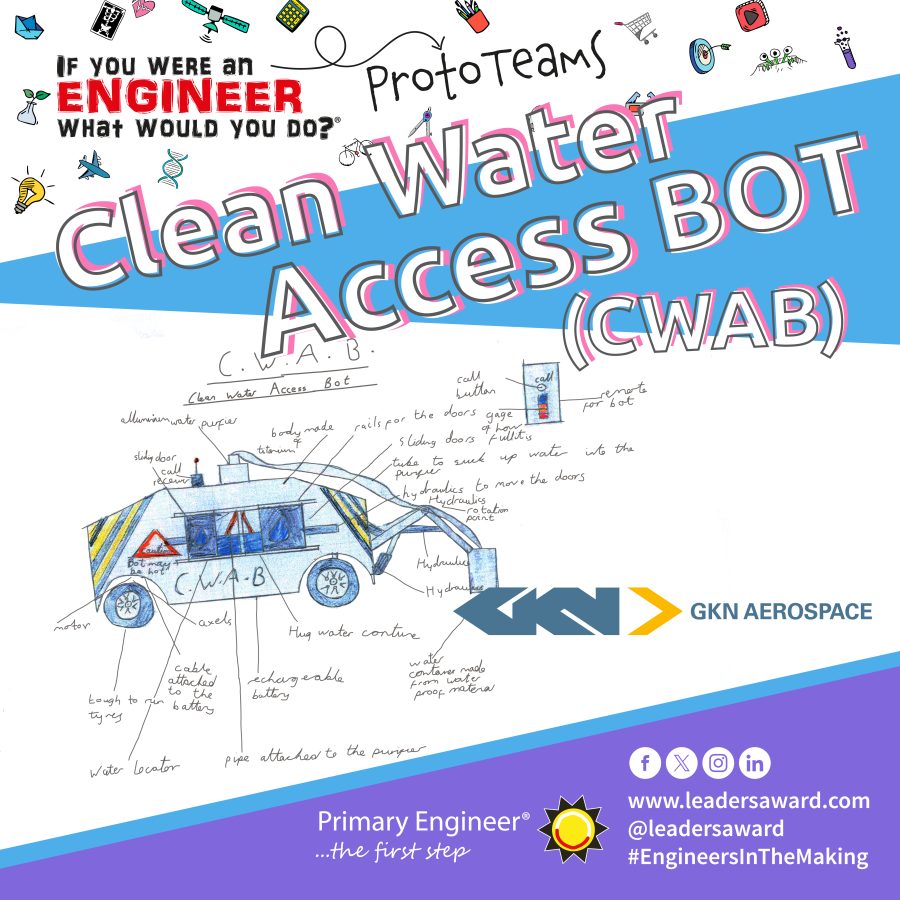

GKN Aerospace creating the C.W.A.B

GKN Aerospace will turn Year 5 Pupil Ben’s Clean Water Access Bot into a reality with their prototype as part of a continued partnership between GKN Aerospace and Primary Engineer.

GKN Aerospace are one of our Partners for South West England as part of our annual engineering competition which asks pupils aged 3-19 ‘If you were an engineer what would you do?’ and encourages pupils come up with creative solutions to real-world problems.

GKN Aerospace have selected this design to turn into a prototype over the 2023/2024 academic year which will be unveiled at the next South West England Awards Ceremony and Public Exhibition during the Summer term.

They chose this design because it addresses an important problem – accessibility of water in remote locations.

Beginning the prototype

The GKN Aerospace ProtoTeam is made up of five engineers with a variety of expertise from different projects:

- Dr Ian Gent has a background in chemistry and is working on composites research

- Tom Ramsbottom is developing new composite manufacturing technologies

- Matthew Hunt also works with composites as well as sustainability analysis

- Remo Prior-Calver is involved in sustainability research

- Sam Hargrave is working on machining process development and modelling

With the variety of skill sets in the team such as CAD, part analysis, material science, automation, additive manufacturing, machining, electronics and sustainability analysis, they sat down and used their different perspectives to review the submissions based on several factors:

- Motivation for the prototype (what problem does it solve, who does it benefit, ethical considerations)

- Design complexity (number of parts, size, accuracy & precision requirements)

- Materials required

- Programming complexity

- Budget

- School location

After 3 rounds of down-selection including key stakeholders (such as those responsible for our budget), the team landed on the Clean Water Access Bot (C.W.A.B – a strong acronym is very important!), which performed well in all of the above categories. The prototype addresses an important problem – accessibility of water in remote locations. The team intends to use Ben’s design to create a semi-automated water retrieval system that can pump and store water on-board and transport it to those who need it.

To kick things off the team started with a benchmarking exercise, looking for similar concepts or products that could be used as inspiration. Additionally, Tom, Matt and Sam visited the University of West England (UWE) to have a look at a previous prototype and ask some questions about the process.

The key challenges that stand out for them were:

- The size of the prototype – water capacity would be limited by vehicle size

- Programming the movement of the vehicle

- How the C.W.A.B will load the water into the storage container depending on where it’s in use (a lake would work differently to a well!)

- Water filtration – the water being retrieved in remote locations is unlikely to be clean

- Design for repair – the more complex the design, the harder it is to repair, especially if it is operating in remote/challenging environments

However, the team is excited to now move into the design phase, starting by drawing up some concepts that address these challenges. They plan to focus on their expertise in design and manufacturing to create the water retrieval and storage system, and then potentially retrofit it onto a readily available remote control vehicle. Once the basic functionality is complete, they may consider some extra features such as water filtration.

They have also had a call with Ben and his teacher Megan to talk about the project, listen to his ideas and motivation behind the design, and share some insight on their design concepts. The team look forwards to visiting the school in the near future to update Ben and his class on our progress!