Thales Glasgow creating the Jump Charge prototype – Midpoint Update!

Where we left off…

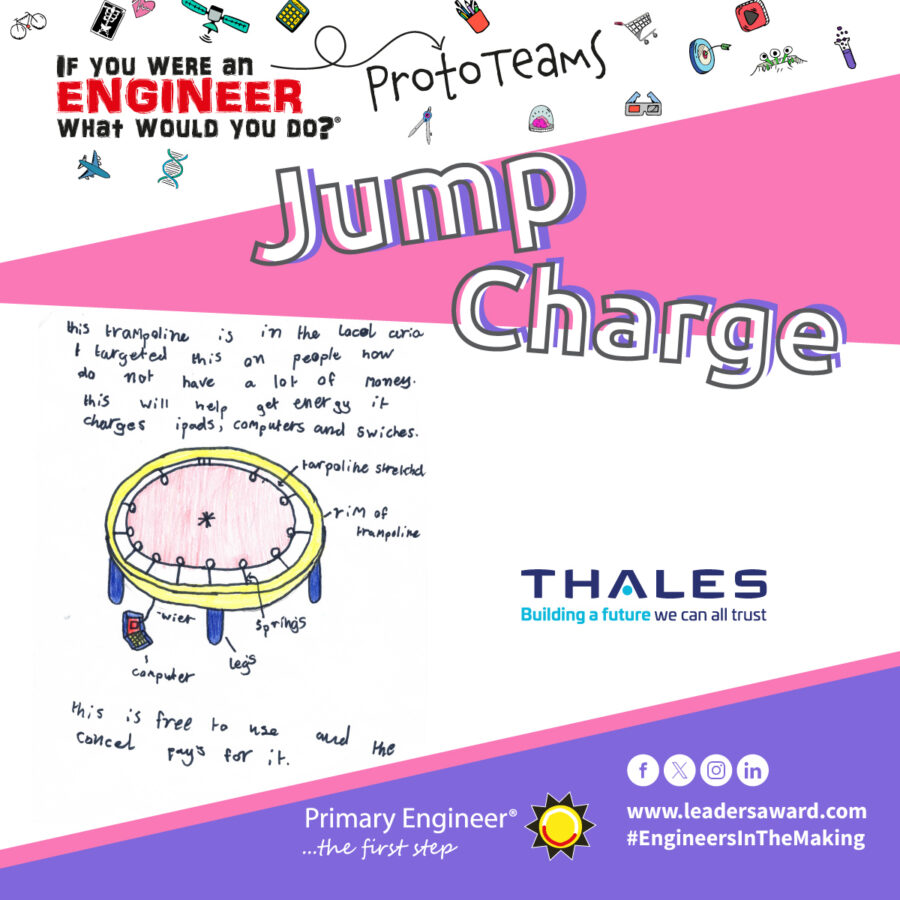

Thales UK, as a national partner of the Leaders Award competition, began turning six pupils’ imaginative engineering ideas into working prototypes, including Adam’s ‘Jump Charge’, a trampoline that generates electricity to charge devices using green energy. Developed by a dedicated team of graduates and apprentices at Thales Glasgow, the prototype aims to combine fun, physical activity, and sustainability. Inspired by the design’s environmental benefits and potential health impact, the team were exploring two engineering solutions: using piezoelectric discs to convert vibrations into electricity, and a spring-magnet motor system that generates power through motion.

Midpoint Update!

It has been a busy and rewarding few months for the team since their last update. Considerable progress has been made on the prototype and the team also had the opportunity to visit young inventor Adam at his school. In addition to running engaging STEM activities for his classmates, they worked with Adam to refine the original design to help maximise its potential.

Following initial procurement and supply chain delays, the team quickly regained momentum. They began testing the piezoelectric discs while simultaneously developing a spring motor concept tailored to fit the trampoline.

Testing the piezo discs involved soldering them into circuits and generating vibrations, sometimes simply by tapping the discs or dropping a ball to measure voltage output. Initial results showed only 1 volt across 10 discs in series. However, a consultation with an experienced electrical engineer revealed that the setup was generating over 20 volts, as seen via an oscilloscope. The discrepancy was due to the limitations of the multimeter, which only captured a brief snapshot of voltage peaks.

On the engineer’s recommendation, the team reconfigured the discs in parallel and introduced capacitors to smooth out voltage spikes and store energy. After several more weeks of testing, they achieved a more stable current enough to power an LED bulb. While the system is still being refined, future improvements, including a hybrid series-parallel setup and experimenting with various capacitor sizes, are expected to significantly enhance performance.

Spring Motor Development

Progress on the spring motor mechanism has been more complex but still promising. The current concept involves a magnet being pulled vertically through a coil using fishing wire connected to the underside of the trampoline mat. Each jump causes the magnet to move, generating electricity through electromagnetic induction.

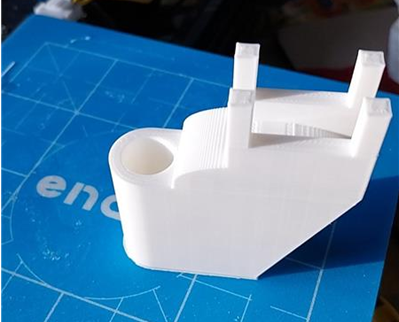

To support this mechanism, a custom 3D-printed bracket has been designed to ensure precise control of the magnet’s movement. While this approach sacrifices the traditional spring component, it successfully integrates both the piezo and electromagnetic ideas into a cohesive prototype. Although final testing has been delayed due to material shortages and the need for smaller magnets, the team is confident this feature will be incorporated successfully.

A Very Special School Visit

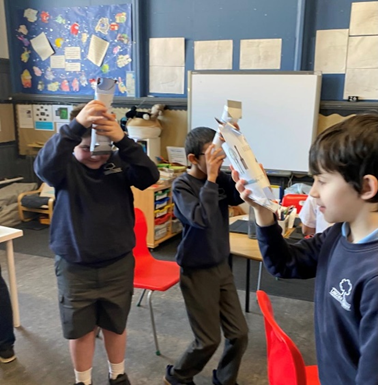

In late February, the team visited Langside Primary School in Glasgow to meet Adam and introduce themselves to his class. After a short presentation on engineering and the project, they ran a STEM activity where students built functional paper periscopes using mirrors. The activity was a great success, with enthusiastic participation from the children, especially once they realised they could keep their creations!

The visit also included a detailed discussion with Adam about the technical aspects of the design. The team introduced the idea of a new charging box, which will house the battery that stores the electricity generated by the trampoline. This box will allow users to safely plug in and charge devices, reducing energy waste. Adam provided a bold red and yellow design, which is currently being brought to life. Although the trampoline has been downsized to a smaller exercise model, every effort is being made to maintain Adam’s original colour scheme.

So what’s the next steps?

The coming weeks will be critical for the successful completion of the prototype. Key tasks include:

- Wiring over 100 piezo discs into combined series and parallel circuits

- Implementing the magnet-based motor mechanism

- Stabilising the electrical current to ensure effective battery storage

- Completing the design and construction of the charging box

- Wiring the battery to the trampoline system

- Finalising the aesthetics

- Conducting thorough final testing

The completed prototype will also be proudly unveiled to Adam and the guests at the Primary Engineer Leader’s Award, ‘If you were an engineer, what would you do?’ Exhibition and Awards event on Thursday, 5th June!